Well today saw the completion of a couple of projects. One being the installation of a Eberspacher (Dometic) Airtronic D2 Diesel Heater and the other mounting a toolbox to the drawbar.

The diesel heater install started with a lengthy decision on where to firstly place the heater and secondly where to mount the air intake and output vents. The heater location was restricted by where the bottom of the heater would end up and keeping it away from the chassis, water pipes and wires. The decision was made to place it under the front lefthand dining seat.

The air intake and output vents were placed up high enough so the kids don't kick them with their heals. The location should allow the output vents to push the hot air down to the rear of the van easily enough.

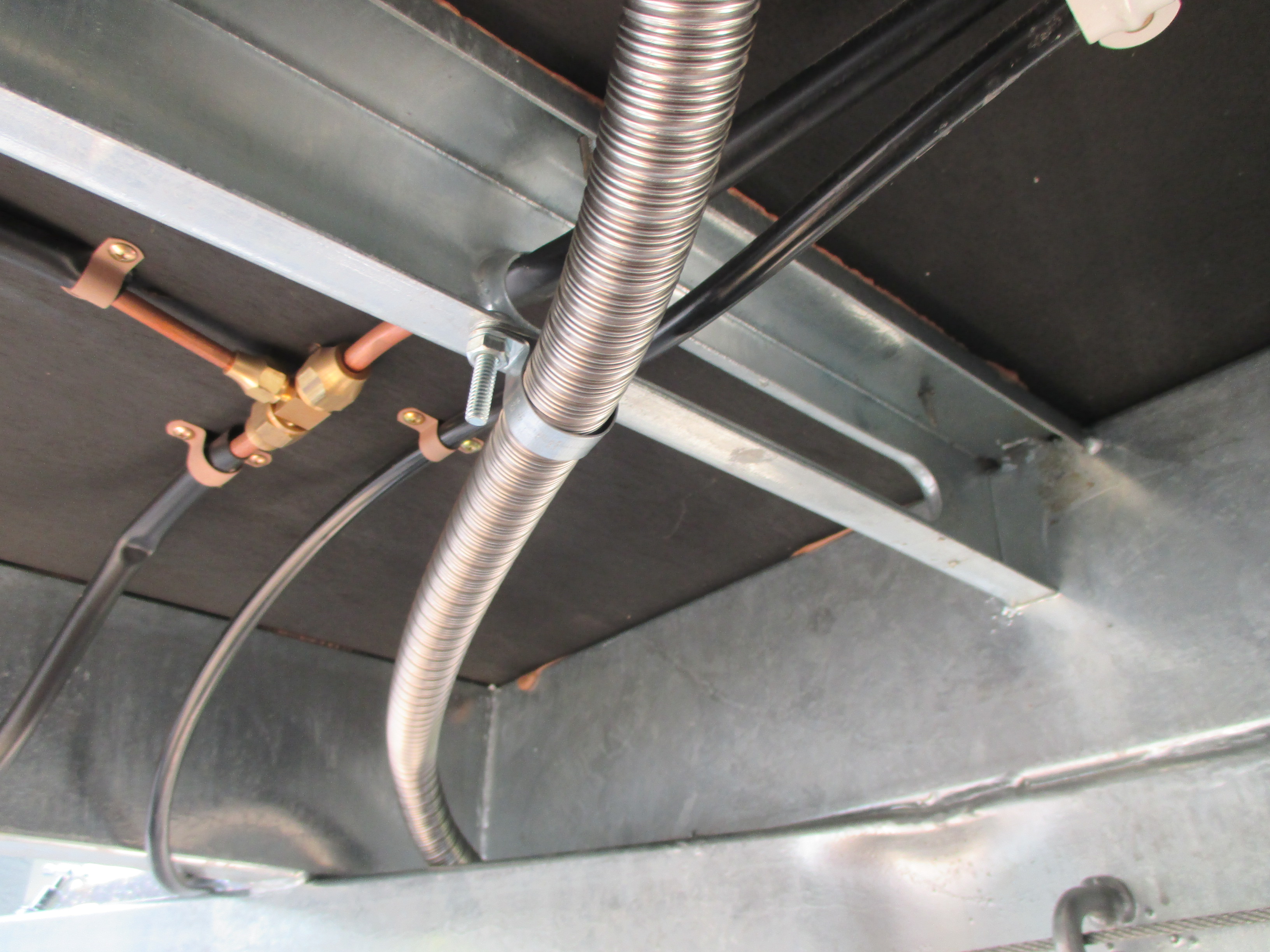

Next job took a few hours under the van to locate and install a suitable path for the exhaust to run. It is advised not to run the exhaust towards the annex side of the van and it should also not extend past the outside wall of the van as it runs extremely hot.

The combustion air intake was connection and strapped away from the exhaust.

I ran the exhaust pipe from the rear of the unit along the floor then under the chassis, back up along the floor to the muffler, ending the tip just above the front drop down jack. A small drain hole was drilled at the lowest point to drain any condensation.

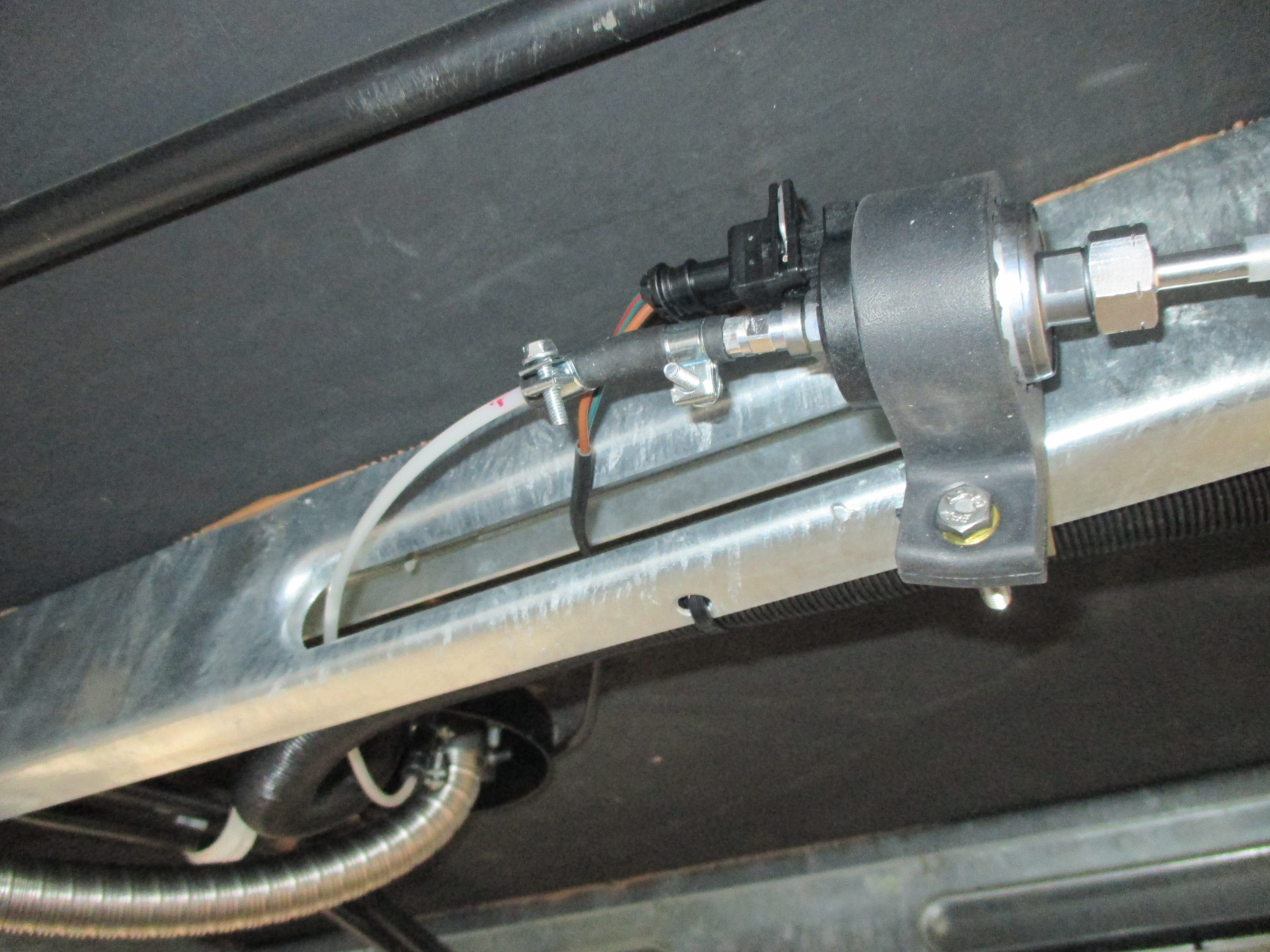

The next job was the dosing pump which must be installed in an upward incline of at least 15 degrees and not more than 35 degrees.

The white fuel line was connected here ensuring it stays well clear of the exhaust. The black fuel line was run back along the chassis and towards the front tool box. Photos of the tool box install will show this.

Next job was back in the van and after a lengthly process of removing every switch, vent, appliance, cover, to route the controller lead to the recommended location of 1.5m above floor level to enable a clear reading for the heat sensor. I located this beside the solar panel controller

on the microwave side. This location was selected as I needed a spot where the rear of the controller could be accessed as the lead runs from the rear.

The final job was to run the 12v power. I connected straight to the battery with 6mm auto cable and installed an isolation switch (as an after thought and after a mid-install inspection suggestion by @cruza driver) This will ensure the kids don't fire up the heater by mistake while they are kneeling on the seats pressing and playing with all those tempting (push me, push me) buttons & controllers.

A quick run down on the total time the instal took was probably about 3 half days, most of the time was planning and double checking before drilling obviously. My biggest holdup was installing a front tool box and relocating the gas bottles. I then secured the 10l diesel tank to the rear of the tool box.

I fired up the heater this afternoon and it ran the dosing pump for about 30 seconds, blew some cold air then shut down. It did this twice so I shut it down, checked the fuel connections, saw there was diesel reaching the white fuel line with a fair few air bubbles so this looked promising. I let it rest for 20 minutes fired it up again and away it went, scorching hot air within a minute or so. The combustion air intake is louder than I thought, but still quiet in comparison. There is an optional air silencer which I might try and get my hands on. The unit itself can be heard running but once the seat cushions are back I think this will be minimal (certainly quieter than the overhead electric heater). The exhaust pipe runs hot as would be expected but would be a concern if camping in long dry grass, just something to keep in mind. The unit and exhaust stayed quite hot for 15 - 20 minutes after shut down. So now that the initial testing is complete, time to take it out into the wild for a proper test. If anyone is thinking of completing an install like this, I'm more than happy to answer any questions you might have.

The diesel heater install started with a lengthy decision on where to firstly place the heater and secondly where to mount the air intake and output vents. The heater location was restricted by where the bottom of the heater would end up and keeping it away from the chassis, water pipes and wires. The decision was made to place it under the front lefthand dining seat.

The air intake and output vents were placed up high enough so the kids don't kick them with their heals. The location should allow the output vents to push the hot air down to the rear of the van easily enough.

Next job took a few hours under the van to locate and install a suitable path for the exhaust to run. It is advised not to run the exhaust towards the annex side of the van and it should also not extend past the outside wall of the van as it runs extremely hot.

The combustion air intake was connection and strapped away from the exhaust.

I ran the exhaust pipe from the rear of the unit along the floor then under the chassis, back up along the floor to the muffler, ending the tip just above the front drop down jack. A small drain hole was drilled at the lowest point to drain any condensation.

The next job was the dosing pump which must be installed in an upward incline of at least 15 degrees and not more than 35 degrees.

The white fuel line was connected here ensuring it stays well clear of the exhaust. The black fuel line was run back along the chassis and towards the front tool box. Photos of the tool box install will show this.

Next job was back in the van and after a lengthly process of removing every switch, vent, appliance, cover, to route the controller lead to the recommended location of 1.5m above floor level to enable a clear reading for the heat sensor. I located this beside the solar panel controller

on the microwave side. This location was selected as I needed a spot where the rear of the controller could be accessed as the lead runs from the rear.

The final job was to run the 12v power. I connected straight to the battery with 6mm auto cable and installed an isolation switch (as an after thought and after a mid-install inspection suggestion by @cruza driver) This will ensure the kids don't fire up the heater by mistake while they are kneeling on the seats pressing and playing with all those tempting (push me, push me) buttons & controllers.

A quick run down on the total time the instal took was probably about 3 half days, most of the time was planning and double checking before drilling obviously. My biggest holdup was installing a front tool box and relocating the gas bottles. I then secured the 10l diesel tank to the rear of the tool box.

I fired up the heater this afternoon and it ran the dosing pump for about 30 seconds, blew some cold air then shut down. It did this twice so I shut it down, checked the fuel connections, saw there was diesel reaching the white fuel line with a fair few air bubbles so this looked promising. I let it rest for 20 minutes fired it up again and away it went, scorching hot air within a minute or so. The combustion air intake is louder than I thought, but still quiet in comparison. There is an optional air silencer which I might try and get my hands on. The unit itself can be heard running but once the seat cushions are back I think this will be minimal (certainly quieter than the overhead electric heater). The exhaust pipe runs hot as would be expected but would be a concern if camping in long dry grass, just something to keep in mind. The unit and exhaust stayed quite hot for 15 - 20 minutes after shut down. So now that the initial testing is complete, time to take it out into the wild for a proper test. If anyone is thinking of completing an install like this, I'm more than happy to answer any questions you might have.